The power steering pump plays an essential role in making vehicle steering effortless and precise. Without it, turning the steering wheel would require significant effort, particularly in heavier vehicles. This article explains the function, importance, and maintenance of this critical automotive component, so let’s dive in and unravel its mysteries.

What Is a Power Steering Pump?

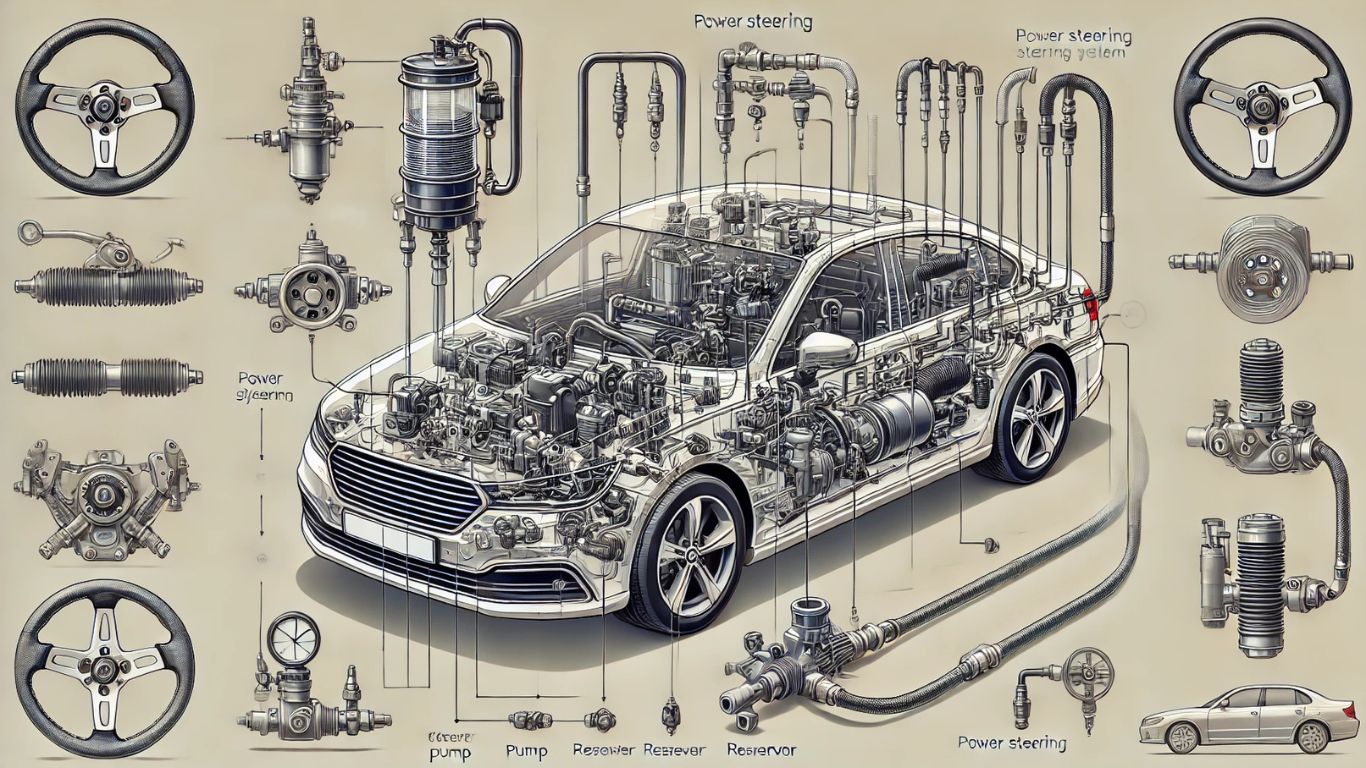

A power steering pump is a vital part of the hydraulic steering system that helps reduce the effort needed to turn a vehicle’s steering wheel. It pressurizes hydraulic fluid, enabling the system to assist in the smooth movement of the wheels. Found in almost every modern vehicle, the pump ensures better control and a comfortable driving experience.

How Does a Power Steering Pump Work?

The power steering pump uses a pulley and belt system connected to the engine. When the engine runs, the pump draws hydraulic fluid from a reservoir and pressurizes it. This pressurized fluid travels through hoses to the steering gear, providing the force needed to turn the wheels with minimal effort.

Key Components of a Power Steering Pump

- Pulley: Drives the pump using engine power.

- Reservoir: Stores hydraulic fluid.

- Pressure Relief Valve: Maintains safe pressure levels.

- Rotors and Vanes: Circulate and pressurize fluid.

Types of Power Steering Pumps

Different vehicles use various types of power steering pumps. Each type is designed to meet specific performance needs and vehicle designs.

1. Vane Power Steering Pump

Most commonly, this pump uses vanes inside a rotor to pressurize fluid efficiently.

2. Roller Power Steering Pump

Rollers are used to create pressure, offering a more compact design.

3. Slipper Power Steering Pump

This type utilizes slipper pads instead of vanes for pressurization, reducing wear and tear.

Signs of a Failing Power Steering Pump

A failing power steering pump can lead to steering problems, compromising safety. Recognizing these signs early can save you from unexpected breakdowns:

- Whining or Groaning Noises: These sounds occur when fluid levels are low or the pump is failing.

- Hard Steering: Increased effort to turn the wheel suggests low fluid pressure.

- Fluid Leaks: Pools of hydraulic fluid under your car indicate a leak in the system.

- Vibrations or Jerky Steering: Inconsistent pressure from the pump causes steering issues.

Common Causes of Power Steering Pump Failure

Understanding why a power steering pump fails can help in preventing such issues.

- Low Fluid Levels: Insufficient hydraulic fluid leads to pump overheating.

- Contaminated Fluid: Dirt or debris in the fluid damages internal components.

- Worn-Out Seals: Aging seals may cause leaks and loss of pressure.

- Belt Damage: A broken or loose belt prevents the pump from functioning.

How to Check and Maintain Your Power Steering Pump

Regular maintenance ensures the longevity of your power steering pump and optimal vehicle performance.

1. Inspect Fluid Levels Regularly

Always check fluid levels in the reservoir and top it up as needed. Look for discoloration or contamination, as dirty fluid can harm the system.

2. Listen for Unusual Noises

Whining sounds when turning the wheel should be addressed promptly. These noises often signal low fluid or a failing pump.

3. Examine for Leaks

Inspect the area beneath your vehicle for hydraulic fluid, which may indicate a leak. Addressing leaks early prevents further damage.

4. Check Belt and Pulley Condition

A loose or damaged belt affects the pump’s efficiency. Ensure the belt is properly tensioned and free of cracks.

How to Replace a Power Steering Pump

When the power steering pump becomes irreparable, replacing it is necessary. While this process is often handled by mechanics, understanding the steps involved is beneficial.

Steps for Replacing the Pump

- Drain Hydraulic Fluid: Remove the fluid to avoid spills during replacement.

- Disconnect Hoses: Carefully detach the hoses connected to the pump.

- Remove the Old Pump: Unscrew bolts and take out the malfunctioning pump.

- Install the New Pump: Secure it in place and reconnect the hoses.

- Refill Fluid: Add fresh hydraulic fluid and bleed the system to remove air bubbles.

Advantages of a Well-Maintained Power Steering Pump

A functioning power steering pump offers several benefits:

- Smooth Steering: Provides effortless wheel turning.

- Improved Control: Enhances vehicle maneuverability.

- Reduced Wear: Protects other components from excessive strain.

Hydraulic vs. Electric Power Steering Pumps

Modern cars increasingly feature electric power steering systems, which differ from traditional hydraulic setups.

Hydraulic Power Steering Pumps

These rely on pressurized fluid and offer precise control, especially at low speeds.

Electric Power Steering Pumps

Powered by an electric motor, they are more energy-efficient and require less maintenance but lack the tactile feel of hydraulic systems.

Can You Drive With a Bad Power Steering Pump?

Driving with a failing power steering pump is not recommended. Although it is possible, the effort required to steer increases significantly, posing a safety risk. Additionally, a damaged pump may lead to further complications, including increased wear on the steering gear and tires.

What Happens If the Power Steering Pump Fails?

If the pump stops working altogether, the steering system reverts to manual operation. This makes turning the wheel challenging, particularly at low speeds or during parking maneuvers. Immediate repair or replacement is necessary to ensure safe driving.

Cost of Replacing a Power Steering Pump

The cost of replacing a power steering pump depends on factors such as vehicle type, pump brand, and labor charges. On average, it ranges from $300 to $700, with premium models costing more. Regular maintenance can delay such expenses.

Tips for Extending the Life of Your Power Steering Pump

- Use High-Quality Fluid: Always use manufacturer-recommended hydraulic fluid.

- Perform Regular Inspections: Detect and fix minor issues before they escalate.

- Avoid Overturning the Wheel: Holding the wheel at maximum turn strains the pump.

- Replace Belts and Hoses: Worn-out components should be replaced promptly.

Environmental Impact of Power Steering Pumps

Traditional hydraulic power steering systems consume energy continuously, even when not turning. Electric systems, on the other hand, only use energy as needed, reducing fuel consumption and emissions. Upgrading to electric systems is an eco-friendly choice.

The Future of Steering Systems

Advancements in steering technology are shifting towards fully electronic and automated systems. While hydraulic power steering pumps remain common, the growing adoption of electric steering signifies a major transformation in the automotive industry.

FAQs

What does a power steering pump do?

A power steering pump pressurizes hydraulic fluid to assist in steering, making wheel turns effortless and smooth.

How can I tell if my power steering pump is failing?

Common signs include whining noises, hard steering, fluid leaks, and vibrations.

Can low fluid levels damage the power steering pump?

Yes, insufficient fluid can cause the pump to overheat, leading to damage.

What type of fluid does a power steering pump require?

The fluid type varies by vehicle; always refer to your car’s manual for the recommended hydraulic fluid.

How often should power steering fluid be replaced?

Most manufacturers suggest replacing the fluid every 50,000 miles but check your vehicle’s manual for specifics.

Is it worth upgrading to an electric power steering pump?

For improved efficiency and reduced environmental impact, upgrading to an electric system is a wise choice.